62 are the simplest type pf reactor to design and consist of solid catalyst particles being loaded and packed into the bed. Anammox an abbreviation for anaerobic ammonium oxidation is a globally important microbial process of the nitrogen cycle that takes place in many natural environments.

Chapter 12 Professional Reference Shelf

Academiaedu is a platform for academics to share research papers.

. In the anammox reaction nitrite and ammonium ions are converted directly into. There is a correlation between the amount of charge on the atoms and their catalytic activity. In more recent reactor designs the medium usually plastic is submerged in effluent and air is blown into the base of the reactor.

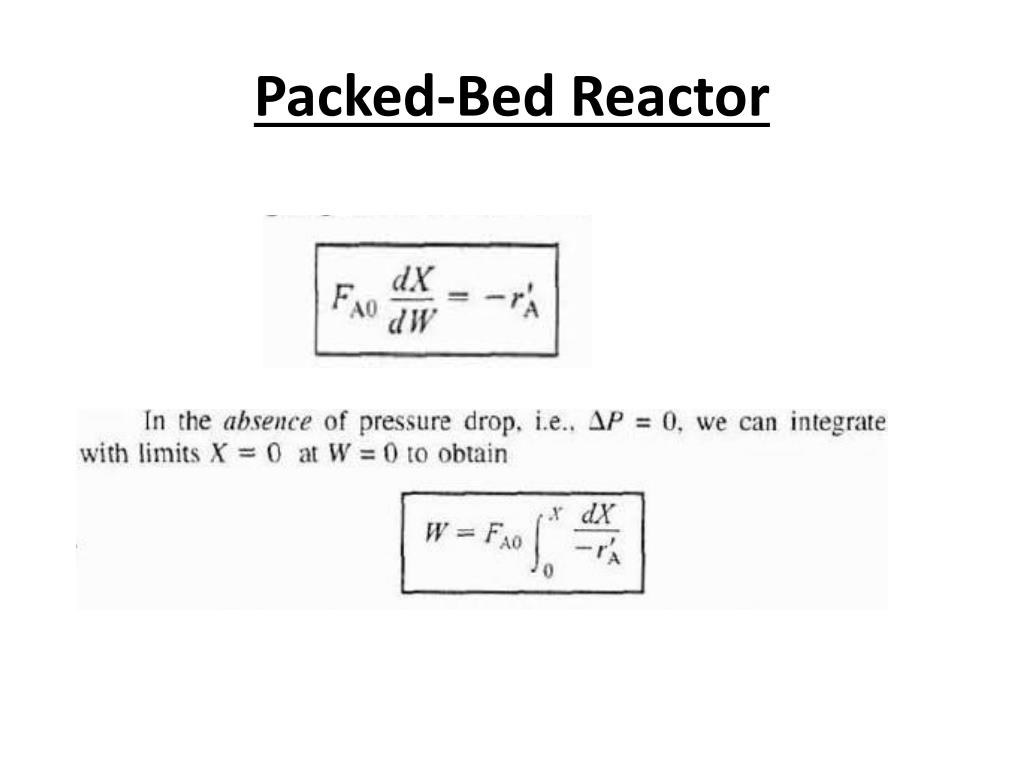

143 Packed-Bed Reactor PBR 18 15 Industrial Reactors 22 CHAPTER 2 CONVERSION AND REACTOR SIZING 31 21 Definition of Conversion 32 22 Batch Reactor Design Equations 32 23 Design Equations for Flow Reactors 35 231 CSTR Also Known as a Backmix Reactor or a Vat 36 232 Tubular Flow Reactor PFR 36 233 Packed-Bed Reactor PBR 37 24 Sizing. Hydrogen is an important chemical intermediate and could be used as a CO 2-free energy carrier in many applications that currently rely on fossil. A criticality accident is an accidental uncontrolled nuclear fission chain reactionIt is sometimes referred to as a critical excursion critical power excursion or divergent chain reactionAny such event involves the unintended accumulation or arrangement of a critical mass of fissile material for example enriched uranium or plutoniumCriticality accidents can release potentially fatal.

The bacteria mediating this process were identified in 1999 and were a great surprise for the scientific community. However there are often problems faced with the plastic feed such as high viscosities low thermal conductivities and irregular shape when being placed inside the reactor. For this catalyst the model proposed by Vanden Bussche and Froment 1996 is able to describe with good precision the reactions of methanol production and the RWGS reaction.

In the traditional percolating filters effluent is sprayed over the medium and trickles through a packed bed with oxygen entering from the air. However the kinetic performance of the FBR normally lies between that of the PBR and the. At high flow rates and low reactor diameters almost ideal plug-flow characteristics may be achieved.

Fixed bed reactors Fig. Calculations show that the active metals in the molten alloys are atomically dispersed and negatively charged. The adiabatic reactor is packed with a fixed bed of 44500 kg of CuZnOAl 2 O 3 commercial catalyst.

Fluidising the bed requires a large power input but once fluidised there is little further energetic input needed to increase the flow rate of the substrate stream through the reactor figure 38. There are also problems faced with small catalyst. Submerged fixed film reactors using plastic media require much less land.

How To Find Volume Of Adiabatic Fixed Bed Reactor

Ppt Conversion And Reactor Sizing Powerpoint Presentation Free Download Id 2646436

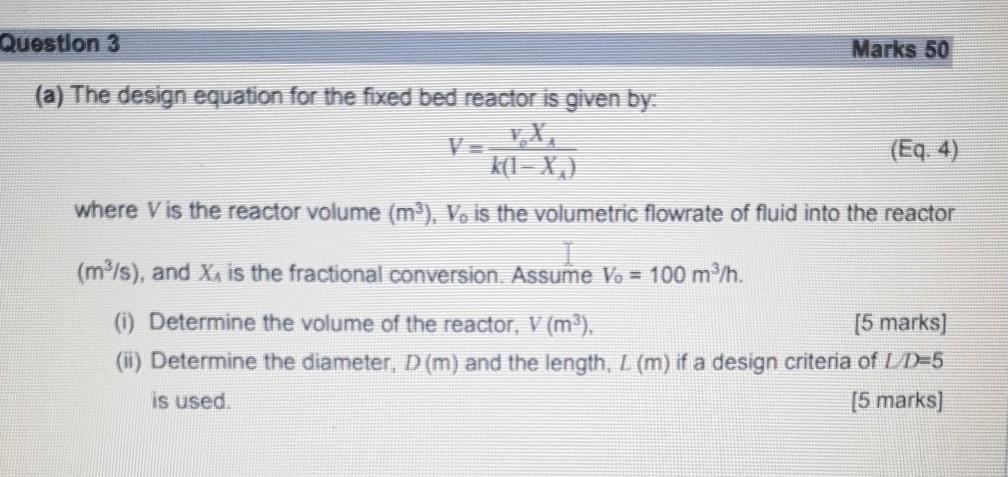

Question 3 Marks 50 A The Design Equation For The Chegg Com

Catalytic Packed Bed Reactor Youtube

Dynamic Non Isothermal Trickle Bed Reactor With Both Internal Diffusion And Heat Conduction Sugar Hydrogenation As A Case Study Sciencedirect

Design Equation Of Packed Bed Reactor Chemical Reaction Engineering Lecture 09 Hindi And Urdu Youtube

0 comments

Post a Comment